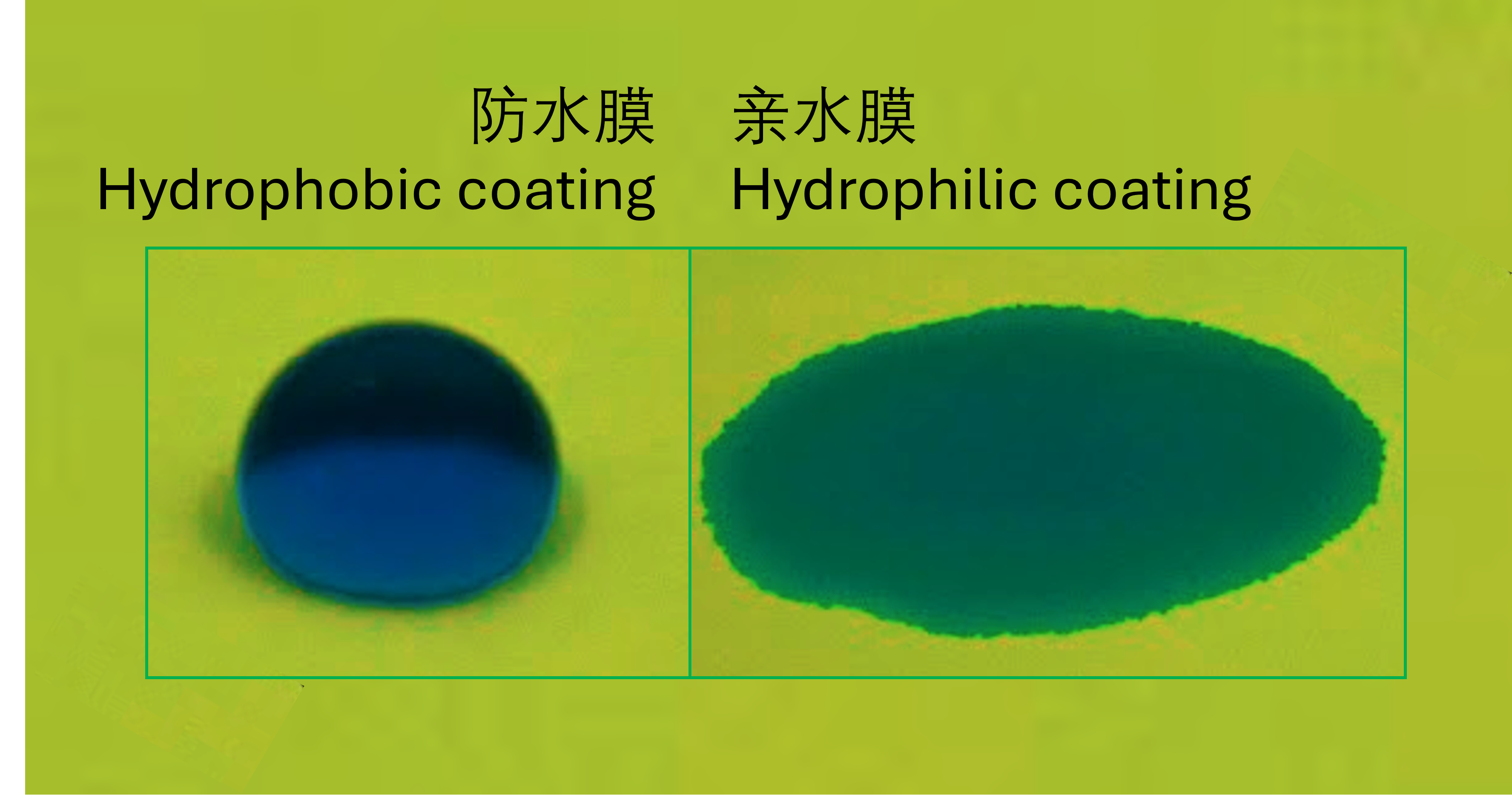

An optical hydrophobic coating is a special coating that is usually applied to the surface of optical devices, such as lenses, prisms, filters, etc. Its main function is to protect optical devices from external environmental factors such as moisture, oil, dust, etc., while maintaining the transmittance and clarity of optical devices.

The role of optical hydrophobic coating:

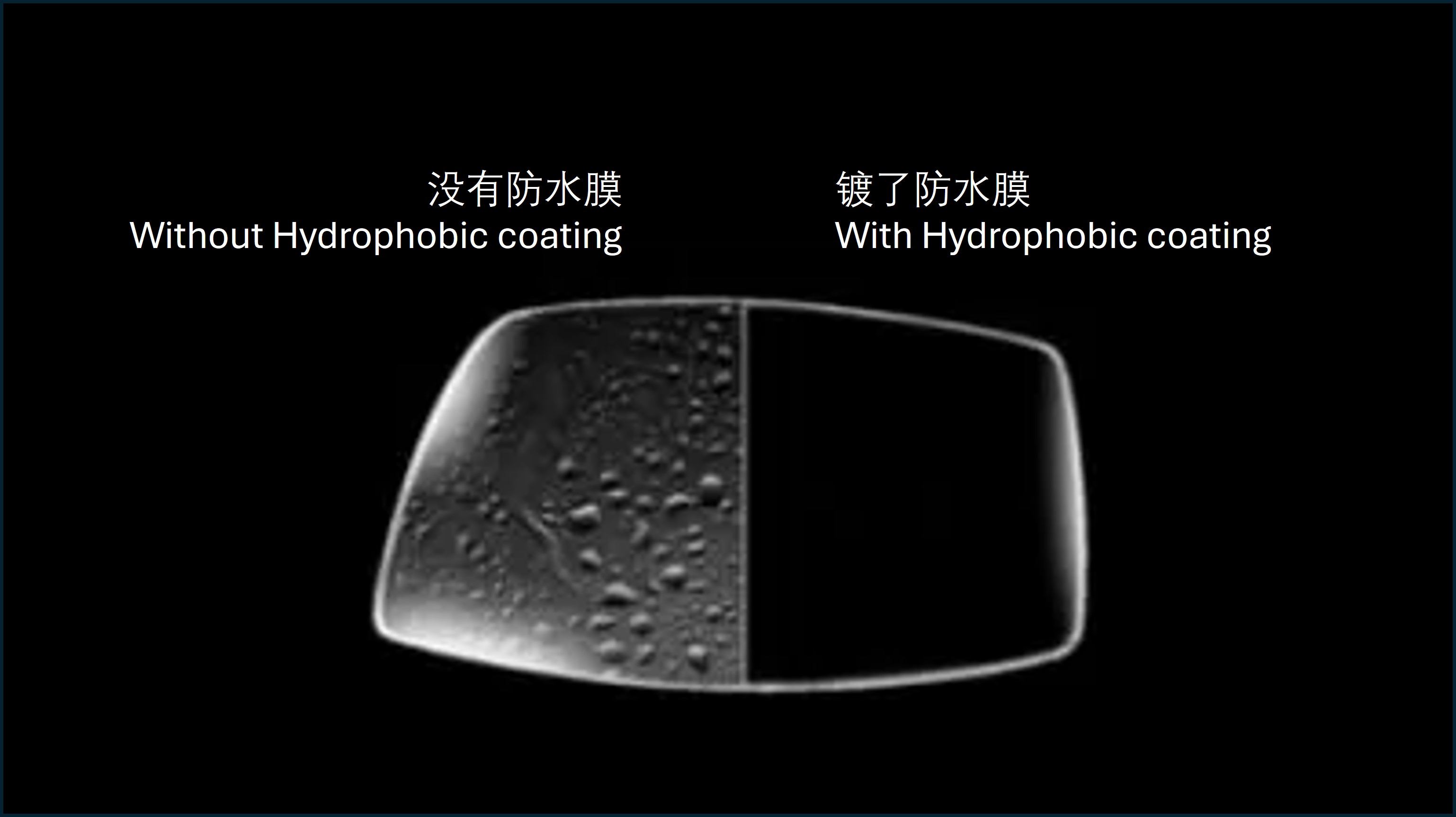

- Waterproof and moisture-proof: Prevent water vapor from condensing on the optical surface, causing fog or water droplets to affect the imaging quality.

- Anti-fouling and anti-oil: Reduce the adhesion of contaminants such as fingerprints and oil, and facilitate cleaning.

- Anti-scratch: Increase the hardness of the optical surface, improve wear resistance, and prevent scratches.

- Enhance durability: Extend the service life of optical devices and reduce maintenance costs.

According to different materials and preparation processes, optical hydrophobic coatings can be divided into many types, the most common ones are:

- Fluorine-based coating materials: have excellent hydrophobic and oleophobic properties, chemical corrosion resistance, and high light transmittance.

- Silane coating materials: have strong bonding with the substrate and good wear resistance, and are often used for substrates such as glass and plastic.

- Nano coating: prepared by nanotechnology, with super hydrophobic and self-cleaning functions.

Optical hydrophobic coatings are widely used in various optical devices, such as:

- Camera lens: protect the lens surface and improve the image quality.

- Telescope: prevent the lens from fogging and observe distant objects clearly.

- Microscope: protect the objective lens and eyepiece and improve the image resolution.

- Glasses: Prevent lenses from fogging and improve wearing comfort.

- Touch screen: Increase the durability of the screen and improve the operating experience.