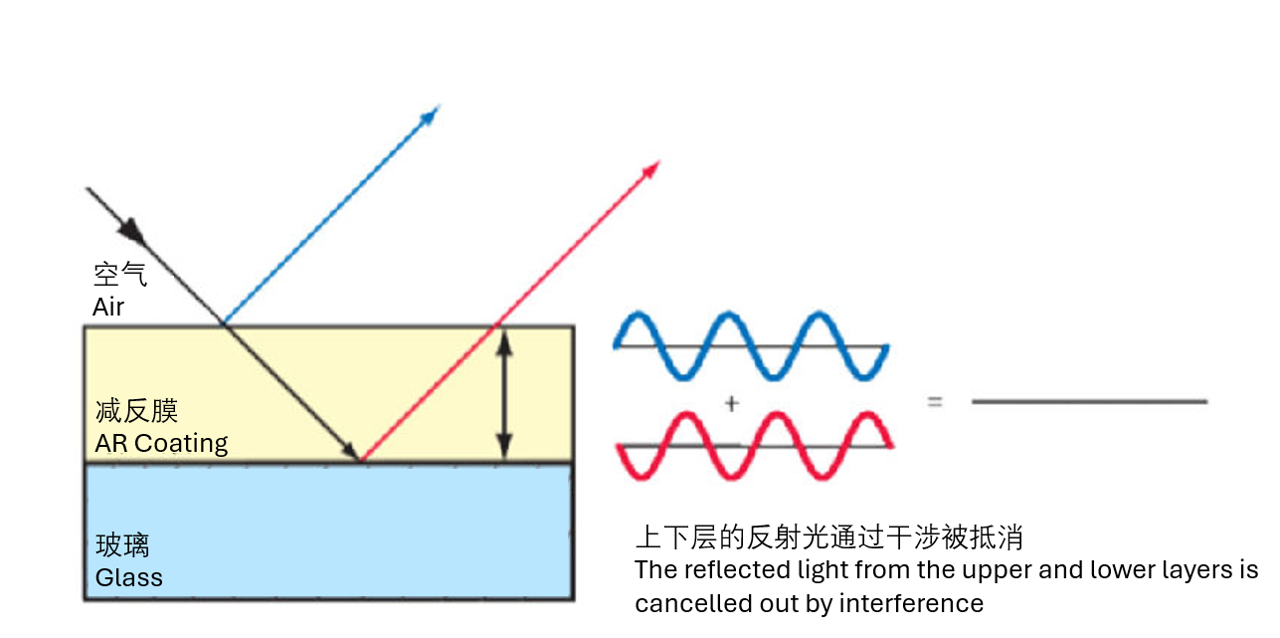

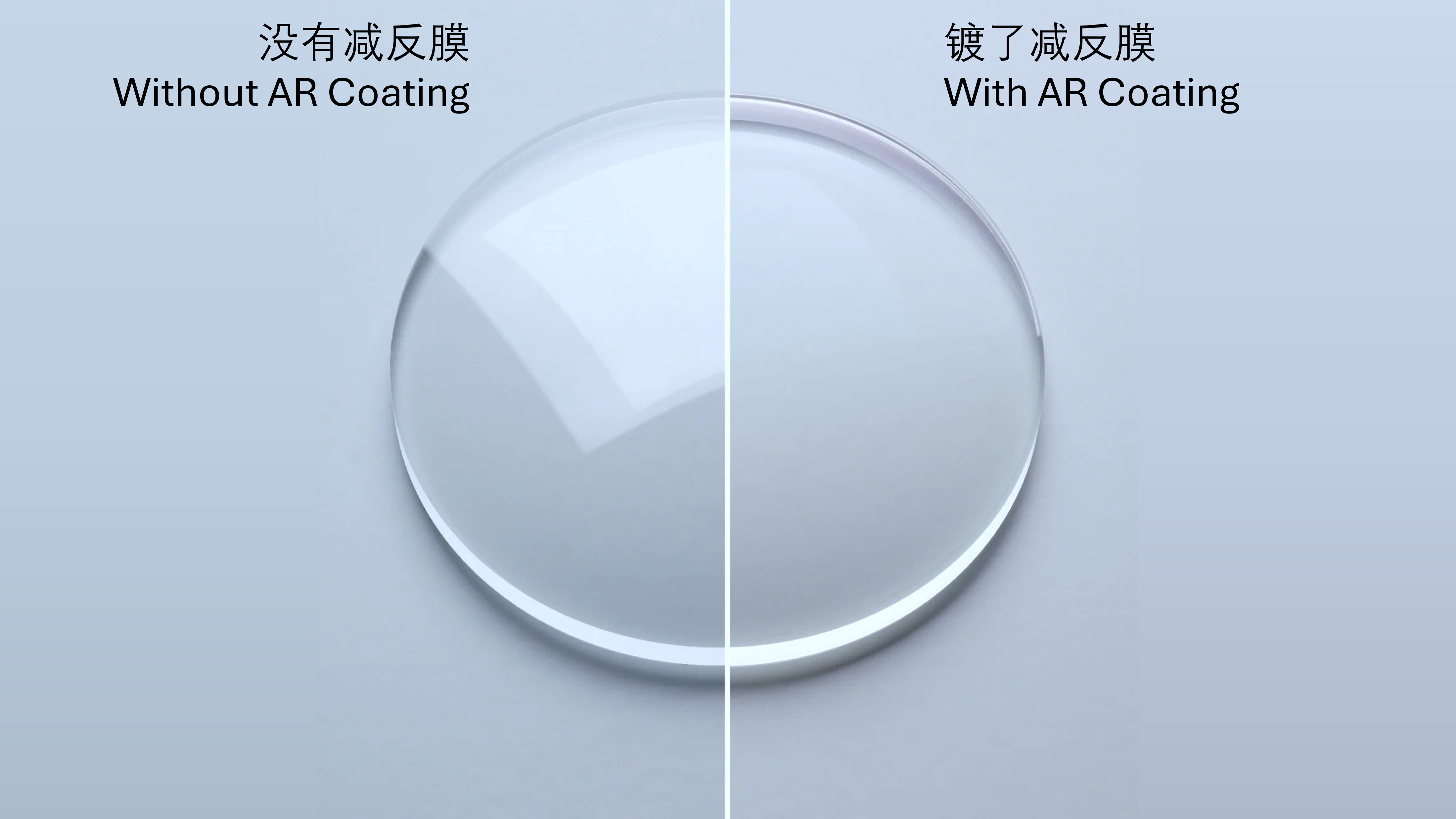

Anti-reflection (AR) coating is a thin film used to reduce the reflected light from the optical surface, thereby increasing the amount of light transmitted and reducing the system stray light. It is widely used in optical components such as lenses, prisms, and plane optical slides.

Anti-reflection coating has a wide range of applications. Here are some of the main applications:

AR coating on solar cells can improve the conversion efficiency of the cells. Silicon material is a semiconductor material, and the principle of solar cell power generation is mainly based on the photoelectric effect. By coating one or more layers of anti-reflection thin film with a refractive index and thickness matching the material of the solar cell, the reflection loss can be minimized, thereby improving the efficiency of the cell.

With the development of the electronics industry and computers, anti-glare and anti-static coating for displays and computer screen protectors have become new application areas for anti-reflection coating. Anti-reflection films can reduce the reflected light of electronic products indoors and outdoors, reduce power consumption, and greatly improve user experience.

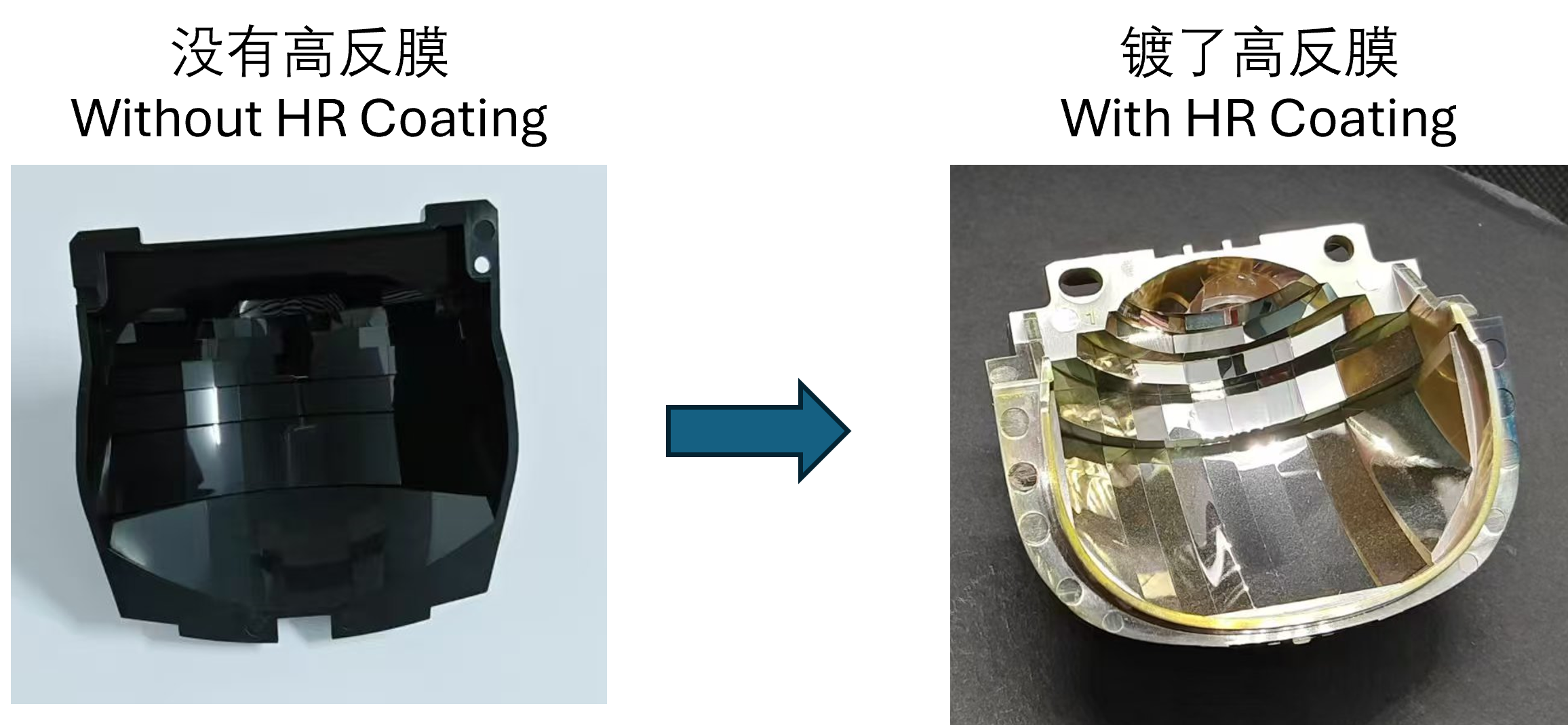

Anti-reflection coatings are widely used on optical components such as lenses, prisms, and plane glass slides. By reducing the reflected light on the optical surface, the light transmittance of these components can be increased, the stray light of the system can be reduced, and the performance of optical instruments can be improved.

Anti-reflection coatings on camera lenses can significantly increase the light transmittance of the lens. For example, for a 35mm auto-zoom camera composed of 18 lenses, if each interface between glass and air has a 4% reflection, the light transmittance of the lens without anti-reflection coating is 27%, while the light transmittance of the lens with one layer of coating (residual reflection 1.3%) is 66%, and the light transmittance of the lens with multiple layers of coating (residual reflection 0.5%) is 85%.

The application of anti-reflection coatings on automobile glass can reduce glare and improve driving safety. Anti-reflective coating can reduce the reflected light from the glass surface, thereby improving visibility.